FD51915E Digital Printing Machine

1. Double THK linear ultra quiet guide rail S-class:During high-speed movement, it can effectively reduce the resistance and noise of the ink carriage, ensuring smooth operation of the guide rail while reducing noise.

2Industrial steel mainframe:The thickness of the base, main unit, and wall panel of the high-strength quenching process on both sides should not be less than 10mm, making the machine run more stably.

3High standard platform and beam calibration method:Ensure that the flatness of the crossbeam and platform is controlled within an accuracy of 3 seconds.

4750w independent servo motor:High precision driven linear decoding, higher accuracy, smaller length error, and more stable performance.

5Flow channel suction printing panel:Reject wrinkles.

6Adopting a constant tension swing rod type paper retraction control system:This ensures that the paper is evenly stressed throughout the entire printing process, and the paper is collected smoothly and tightly to avoid any looseness.

7. Standard 2000m retractable system (measuring 42g of paper); optional 10000 meter source paper base for direct printing of source paper with a diameter<90CM

8. Fiber optic data transmission:Meet the requirements of stable output and transmission speed for high-definition digital printing images.

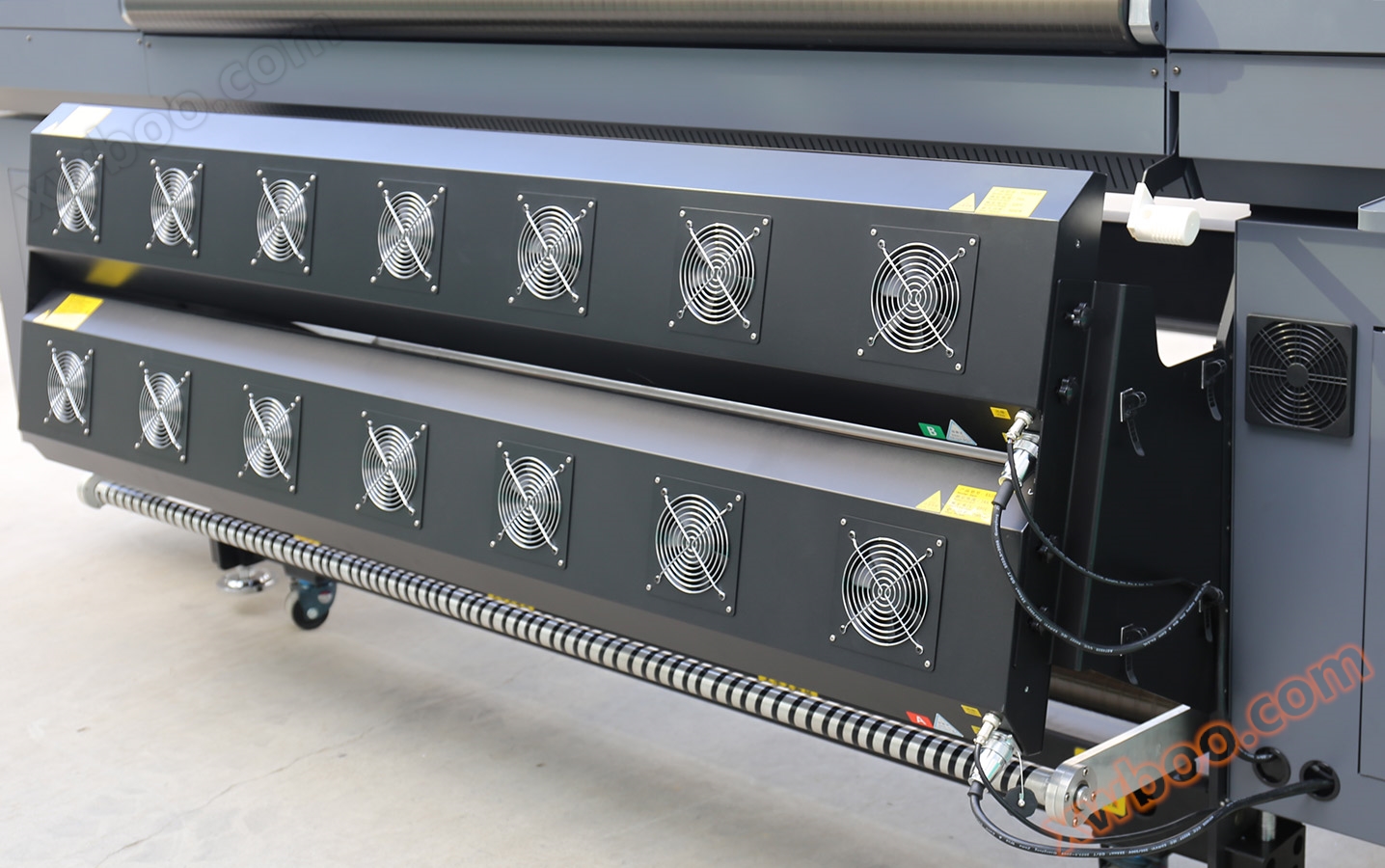

9. equipThree 3600W intelligent segmented drying systems:Ensure more energy-saving while drying.

10.1kw servo motor for material feeding, 0.75kw servo motor for material receiving, equipped with industrial gearbox (10000 meter base)

11. Double drag chain structure design

12. Split ink stack cleaning unit:Advanced intelligent nozzle cleaning and moisturizing device, with long-lasting sealed moisturizing and automatic cleaning effects, making operation and maintenance more convenient.

13. Unique advantages of rubber strip expansion roller

14.NSK bearings, high-quality silent drag chains

15. Optional 15 liter high-capacity continuous ink supply system:Long term continuous ink printing ensures high-quality image output.

dimensional data

Technical parameters and specifications

Equipment model |

FD51915E |

|

Nozzle |

nozzle type |

Epson I3200-A1 |

|

Number of nozzles |

15 of them |

|

Nozzle properties |

Automatic cleaning, automatic flash spray moisturizing function |

|

PRINT SPEED |

1pass |

610㎡/h |

2pass |

300㎡/h |

|

ink |

color profile |

C M Y K |

Ink type |

sublimation ink |

|

| Effective width | 1900mm |

|

Print media |

HEAT TRANSFER PAPER |

|

Media transmission |

Inflatable shaft automatic retraction system |

|

Drying method |

External intelligent air and heat integrated dryer |

|

Moisturizing mode |

Fully sealed automatic moisturizing and cleaning |

|

Rip Software |

Support Maintop6.1, photoprint, ONYX, NeoStampa and other software, with Maintop6.1 as standard |

|

Support image formats |

JPG, TIF, PDF, etc |

|

computer configuration |

operating system |

Win7 64 bit/Win10 64 bit |

hardware requirements |

Hard drive: 500GB or above (recommended to use solid-state drive), 16GB of RAM, graphics card: ATI graphics card with 4GB of RAM, CPU: i7 processor |

|

Interface |

USB3.0 |

|

Standard configuration |

Intelligent drying system, liquid level alarm system, waste ink alarm system |

|

work environment |

Humidity: 35% -65% Temperature: 18-30 degrees |

|

power requirement |

INPUT VOLTAGE |

210-230VAC 50/60 HZ 10A |

printing system |

2200W |

|

drying system |

Maximum power: 10800W |

|

Machine size |

Exterior dimensions: 3600 * 2760 * 1842mm |

|

Packaging size: 3770 * 1120 * 2120mm | ||